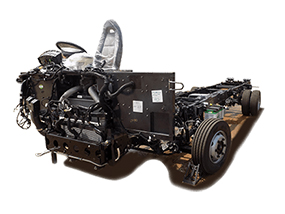

Established in 1945, the Jamshedpur unit is spread over an area of 822 acres and happens to be the company's first manufacturing unit. The Jamshedpur plant's engine factory is responsible for the in-house manufacture of Tata 697/497 naturally aspirated and turbocharged engines, and the 6B series engines manufactured at Tata Cummins. HV Axles Ltd., a wholly owned subsidiary of Tata Motors, manufactures front steer axles - both live and normal, rear drive axles and dummy/ trailer axles. It is currently the sole supplier of large bus axles to the Jamshedpur and Lucknow plants of Tata Motors. The company also manufactures all major axle components such as front axle beam, stub axles, front & rear wheel hubs, differential, axle gears (crown wheel, pinion, bevel gear & shaft gear), banjo axle beam, swivel heads, constant velocity shafts etc. HV Axles Ltd. is a leading manufacturer of automotive transmissions, components, gearboxes and engineering applications for a wide range of medium and heavy commercial vehicles.